We are proud to announce that as of December 2019, the ForgeFlow Demand Driven software has achieved the Demand Driven Sales & Operations Planning (DDS&OP) compliance by the Demand Driven Institute.

What is Demand Driven Sales & Operations Planning (DDS&OP)

DDS&OP is one of the key components of the Demand Driven Adaptive Enterprise Model, and works together with the Demand Driven MRP (DDMRP) and Adaptive S&OP. This model, as defined by the Demand Driven Institute, allows enterprises to sense market changes, adapt to complex and volatile environments, and develop market driven innovation strategies.

© Copyright 2019 Demand Driven Institute. Used with permission

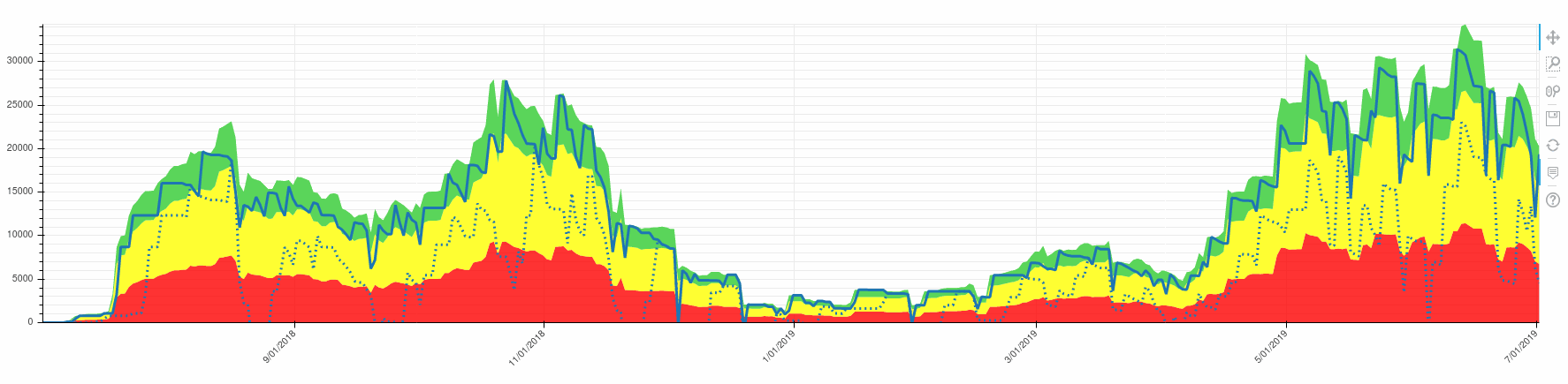

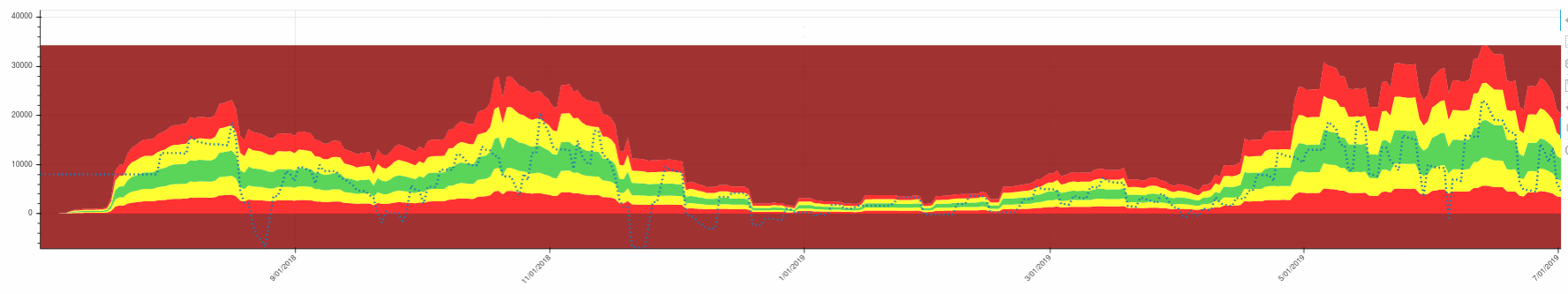

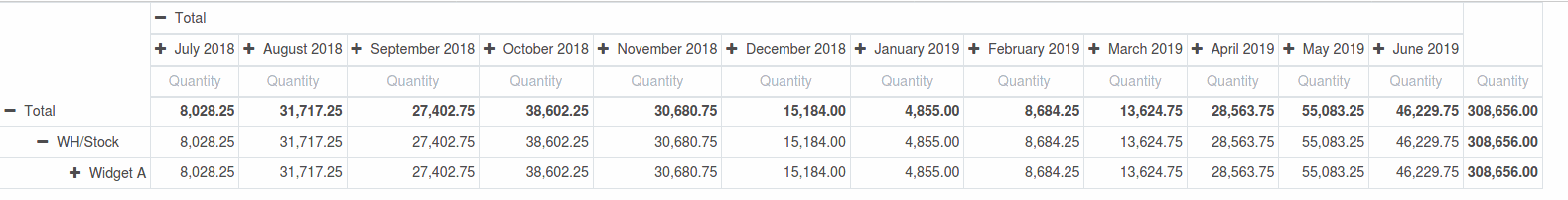

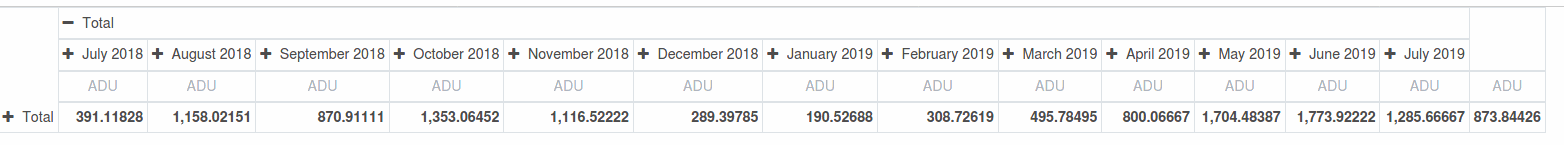

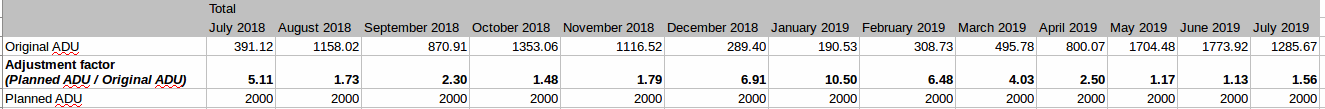

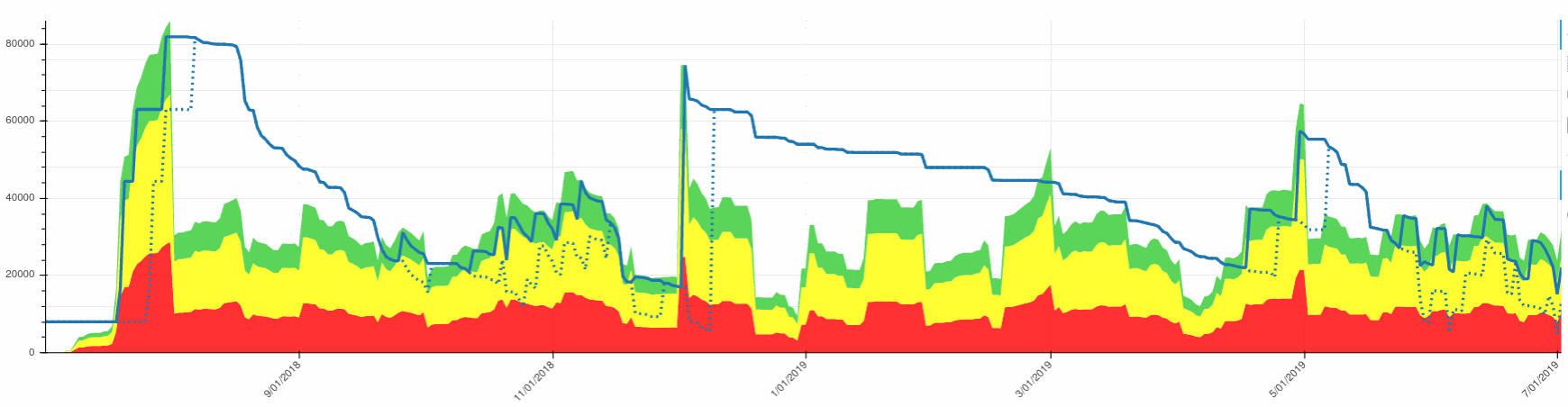

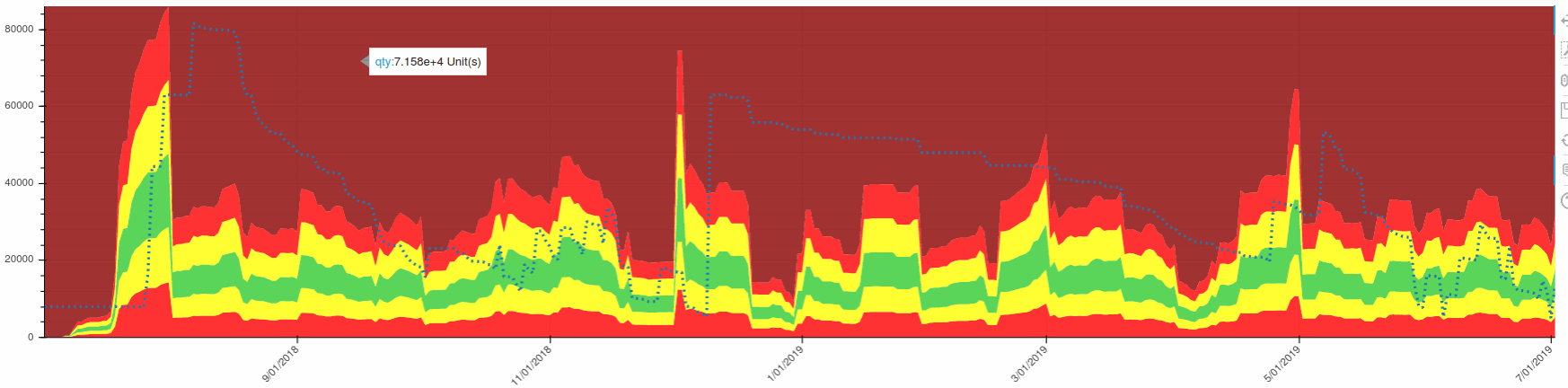

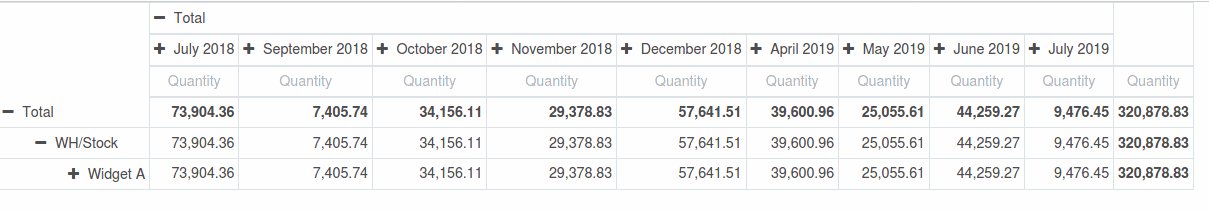

Demand Driven Sales & Operations Planning (DDS&OP) takes the business plan parameters (like sales forecasts, new warehouse availability, etc..) from the Adaptive S&OP component, and configures the Demand Driven Operating Model (DDOM) by means of setting the model parameters (such as buffers, buffer settings, demand adjustment factors), that define the capabilities to achieve expected results.

Demand Driven Sales & Operations Planning (DDS&OP) helps to align your corporate strategy with the operational horizon. It allows to simulate various scenarios based on the business plan parameters and use the planned model parameters to evaluate the impact on the company's capacities and financials. This scenario-based modelling allows planners to identify options for their tactical planning and recommend and implement changes to the Operating Model.